Discover the Different Kinds Of Screen Printing Techniques for Your Following Task

Screen printing provides a varied variety of strategies that can improve any type of imaginative project. From typical techniques like serigraphy to modern-day advancements such as direct-to-garment printing, each approach has its unique benefits. Specialty alternatives, consisting of metallic and environment-friendly inks, introduce much more possibilities. Understanding these techniques can substantially influence the last outcome. The obstacle lies in picking the most appropriate approach for particular needs and wanted results. What elements should one think about?

The Fundamentals of Screen Printing

Although screen printing might seem complicated, it is essentially a straightforward procedure that includes transferring ink through a mesh screen onto different surface areas. The strategy begins with the creation of a pattern, which defines the style to be published. This pattern is affixed to a mesh screen, usually made from polyester or nylon. As soon as the stencil is in location, ink is related to the screen and pushed through the mesh using a squeegee, resulting in the wanted pattern being published on the underlying material.

Screen printing can be performed on a broad variety of substratums, including plastic, material, and paper, making it a versatile choice for different tasks. The procedure enables vivid shades and complex designs, making it prominent in sectors such as art, marketing, and style. Recognizing these fundamentals equips individuals with the fundamental expertise required to check out advanced methods in screen printing.

Traditional Screen Printing Techniques

Traditional screen printing strategies have been used for centuries, preserving the workmanship and virtuosity of this approach. This technique utilizes a mesh screen to transfer ink onto a substrate, such as textile or paper, allowing for resilient and vibrant designs. The process starts with producing a stencil, which blocks specific areas of the screen to manage where the ink will certainly be used.

One prominent method is serigraphy, frequently used for restricted editions and artistic prints. One more is the usage of water-based inks, which are environment-friendly and provide a soft feel on fabrics - 10:9 Design contact. Furthermore, typical approaches can consist of hands-on printing, where craftsmens apply ink with a squeegee, guaranteeing precision and attention to detail

These strategies remain valued in the market for their tactile quality and the unique textures they create, appealing to both customers and developers who appreciate the heritage of screen printing.

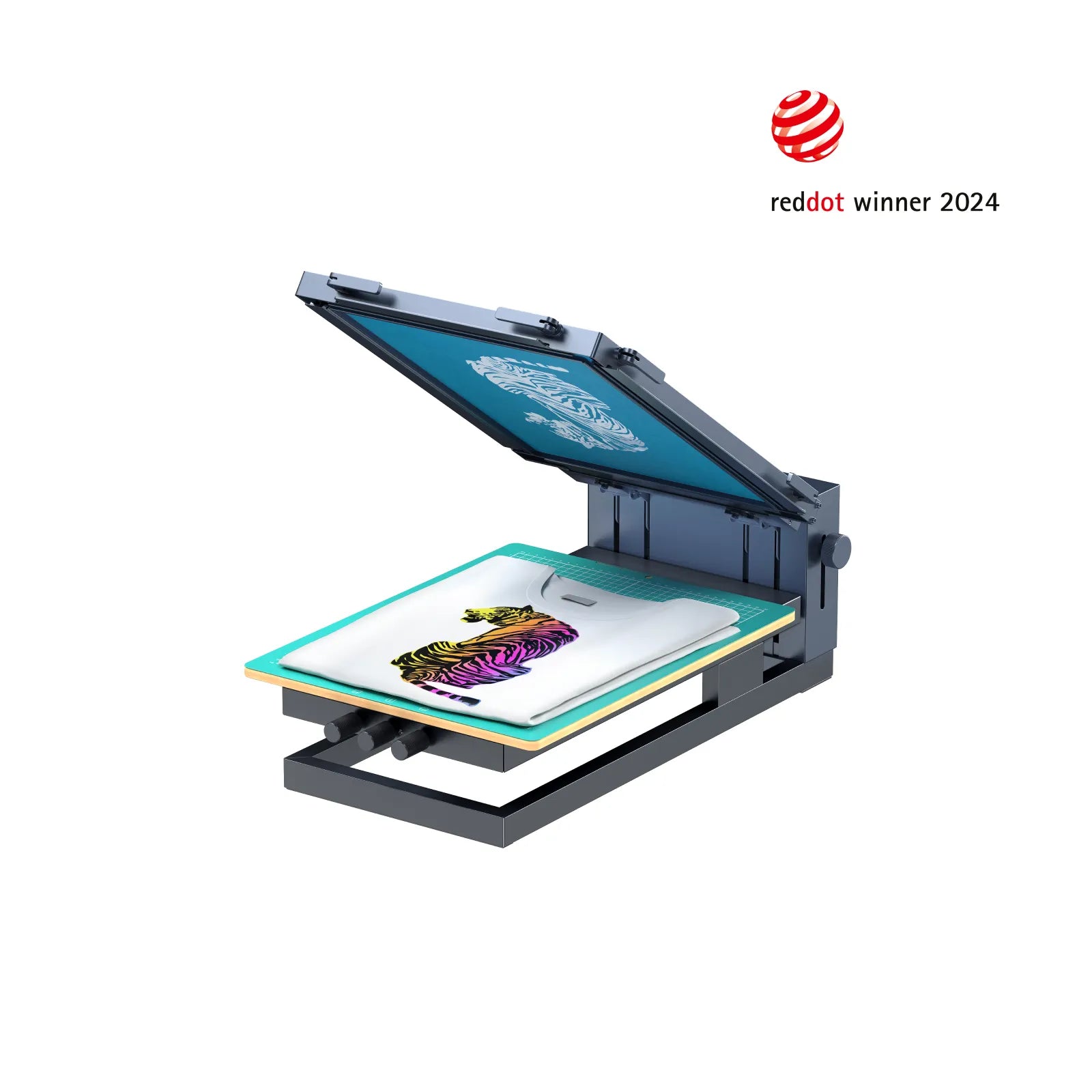

Digital Screen Printing Innovations

As the demand for faster production and personalization in the printing sector has actually surged, digital screen printing innovations have actually arised as a game-changer. This innovation mixes typical screen printing approaches with electronic procedures, permitting rapid prototyping and intricate styles that were previously tough to achieve. One significant development is the introduction of direct-to-garment (DTG) printing, which helps with top notch, full-color prints on different textiles without the demand for displays. Additionally, advancements in ink formulations have caused eco-friendly options that maintain dynamic shades while reducing environmental effect. Using automated systems further improves manufacturing, lowering labor costs and improving accuracy. These advancements not just cater to tiny batch orders and individualized styles yet likewise enable quicker turn-around times, making them perfect for organizations focused on conference consumer needs in a busy market. Digital screen printing, consequently, stands for an essential advancement in the domain of printing strategies.

Specialty Screen Printing Approaches

Discovering specialty screen printing methods reveals a diverse variety of techniques that press the boundaries of creativity and functionality in the printing sector. Among these, glow-in-the-dark inks offer an one-of-a-kind visual result, making styles come active in low-light problems. Metallic inks, known for their glittering coating, include a touch of high-end to printed products. An additional innovative approach is discharge printing, which gets rid of color from the fabric rather than including ink, resulting in a soft, classic feel. High-density printing produces a raised texture externally, enhancing tactile interaction. In addition, water-based inks are getting appeal for their vivid colors and lowered ecological impact. Each of these specialized methods accommodates specific style requirements, enabling brand names and musicians to produce standout items that resonate with their audiences. By leveraging these approaches, organizations can raise their screen printing tasks to brand-new heights, making certain remarkable perceptions.

Eco-Friendly Screen Printing Options

Environmentally friendly screen printing choices are acquiring grip as the sector moves in the direction of sustainability. Lasting ink options and the usage of eco-friendly products are key elements in minimizing the environmental effect of the printing procedure. By adopting these techniques, screen printers can contribute to a more sustainable future while preserving high-grade results.

Lasting Ink Selections

Biodegradable Materials Use

As the screen printing industry advances, the incorporation of eco-friendly materials is becoming significantly important for ecologically aware practices. Producers and developers are now checking out inks and substratums made from natural, renewable energies that decay more effectively than standard equivalents. These biodegradable choices minimize plastic waste and decrease environmental impact, lining up with the growing need for lasting products.

Typical examples consist of water-based inks and natural cotton fabrics, both of which decrease hazardous chemicals and advertise eco-friendliness. Brand names that adopt these materials usually improve their market charm, bring in consumers who prioritize sustainability. As understanding of ecological problems remains to rise, the shift towards naturally degradable materials in screen printing is likely to acquire momentum, fostering their explanation a greener industry standard.

Choosing the Right Technique for Your Project

Exactly how can one figure out one of the most suitable screen printing method for a particular task? The decision rests on several factors, consisting of the product to be printed on, the complexity of the style, and the desired production volume - 10:9 Design Company. As an example, direct-to-garment printing is ideal for detailed designs with various colors, while standard screen printing succeeds for bigger runs of easier graphics

In addition, consideration of the end-use of the published product is important. For outdoor applications, strategies that supply durability and weather condition resistance, such as plastisol ink, might be preferred. On the other hand, environmentally-conscious projects might profit from water-based inks or eco-friendly materials.

Inevitably, comprehending the job's special needs permits for an enlightened choice, making certain both visual allure and useful durability. By assessing style intricacy, material compatibility, and production range, one can properly pick one of the most appropriate screen printing method to fulfill their task's goals.

Regularly Asked Questions

What Is the History of Screen Printing?

Screen printing stemmed in old China around 1000 ADVERTISEMENT, developing with Japan and Europe. By the 20th century, it came to be prominent in industrial art and style, revolutionizing exactly how styles were created and dispersed around the world.

Exactly how Do I Prepare Art Work for Screen Printing?

To prepare artwork for screen printing, one have to ensure high resolution, use an ideal color setting, develop separate layers for each shade, and convert text to describes, assuring compatibility with the printing procedure and wanted outcome.

What Materials Are Finest for Screen Printing?

The ideal materials for screen printing include high-grade inks, durable screens, and appropriate substratums like cotton, polyester, or blends. In addition, using suitable emulsion and squeegees can improve the printing procedure and last outcomes.

Can I Evaluate Publish at Home?

Yes, screen printing in your home is possible. With the appropriate products, setup, and techniques, individuals can develop top my review here notch prints. However, cautious factor to consider of work area and devices is crucial for effective results.

What Are Usual Errors in Screen Printing?

Usual errors in screen printing consist of incorrect direct exposure times, insufficient ink consistency, imbalance of screens, inadequate cleansing of products, and disregarding to examine prints. These mistakes can compromise the high quality and accuracy of the final product.

Screen printing might seem facility, it is fundamentally a straightforward process that entails moving ink with a mesh screen onto different surface areas. As the need for faster production and customization in the try here printing sector has surged, digital screen printing advancements have actually emerged as a game-changer. Checking out specialty screen printing techniques exposes a diverse array of techniques that push the borders of creativity and functionality in the printing sector. The ideal products for screen printing consist of high-grade inks, sturdy displays, and ideal substratums like cotton, polyester, or blends (10:9 Design reviews). Usual blunders in screen printing consist of inappropriate direct exposure times, insufficient ink uniformity, imbalance of displays, insufficient cleaning of products, and neglecting to examine prints